The Operation We Aim For

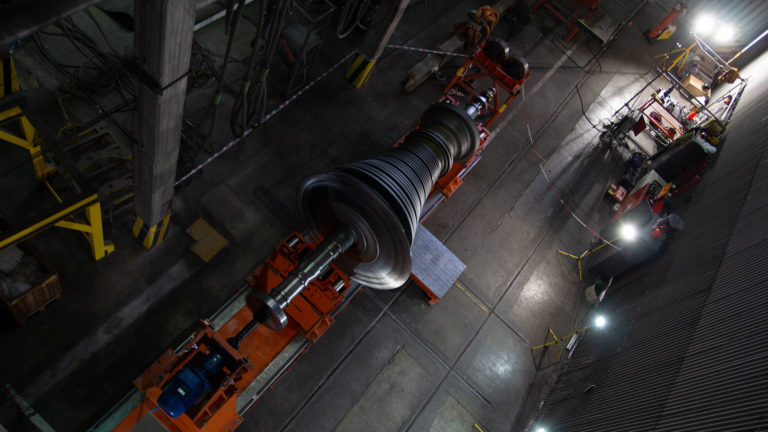

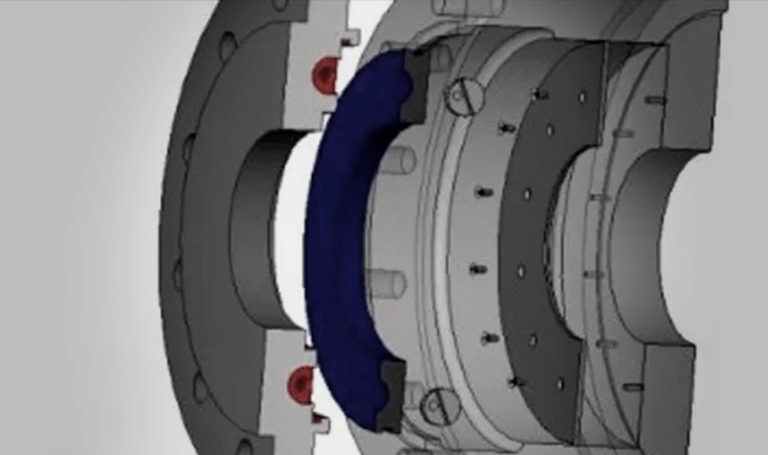

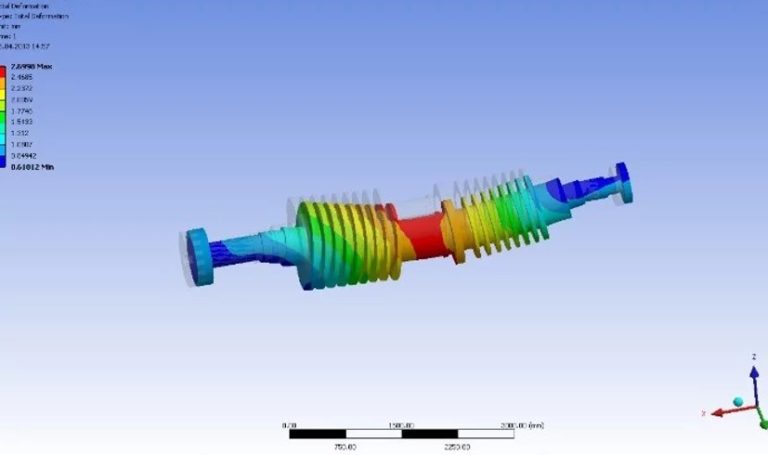

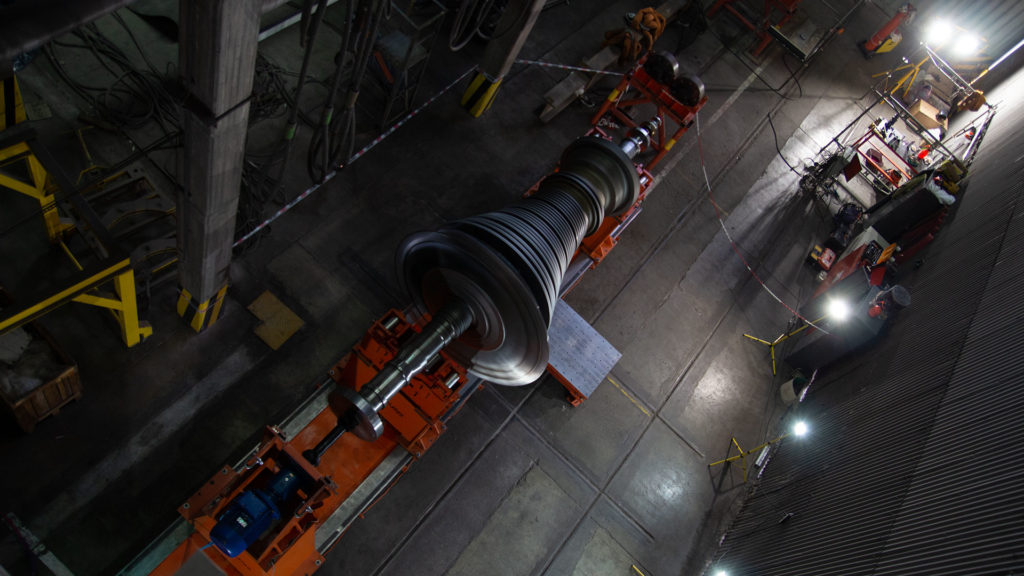

The MB100 is a transportable & customizable system that combines rotor machining capabilities and precise low-speed balancing in a single machine, designed and built in compliance with EU 2023/1230 standards.

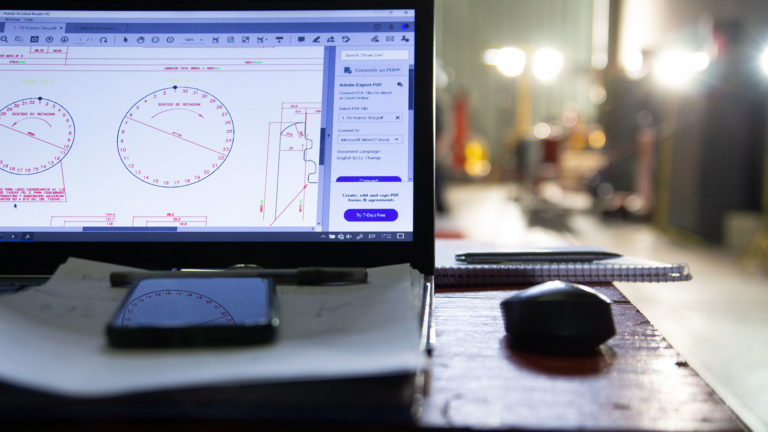

Built for your specs – Configure parameters for your exact rotor types and requirements

Machine + balance in one – Lathe and soft-bearing balancing integrated in a single machine.

Take it anywhere – Balance and machine rotors on-site, at any facility or field location, by simply transporting the machine.

Faster, cost-efficient operations – Shorten schedules and reduce costs with increased operational control.

Reduced transport risk – Keep rotors on-site and avoid logistics, delays, and handling damage.

Grow your capabilities – Balance and machine rotors when you decide with your own engineers and technical team. ↓