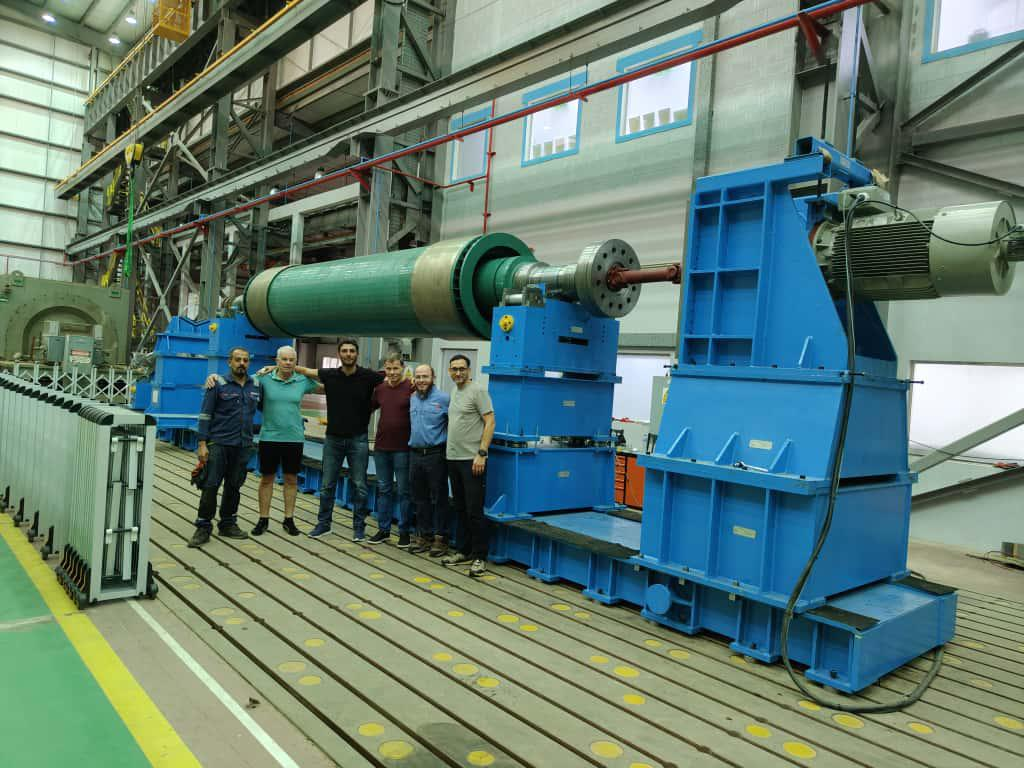

The Machine

The MB100 is a modular & transportable system that combines precise low-speed balancing and rotor machining capabilities in a single machine, built in compliance with EU 2023/1230 standards.

It is designed and supported by ex-OEM engineers to enable low speed balancing of steam turbine, gas turbine and electrical generator rotors, weighing up to 100 tons.